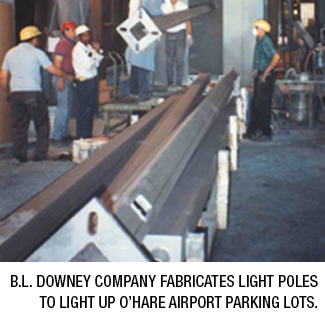

B.L. Downey Company has been fabricating and assembling round, square, tapered, and decorative light poles and other fabricated metal products for nationwide distribution since 1956.

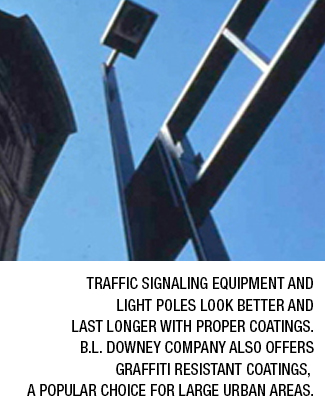

After fabrication, light poles are carefully prepared for coating, and then coated to specifications from cities, towns, and states. B.L Downey Company’s specialized anti-graffiti coating process and formula is ideal for light poles and other public area metal products (benches, trashcan protectors, bus shelters, etc.). Graffiti is simply wiped off with mineral spirits so that the coating and the metal it protects remain unharmed.

B.L. Downey Company has a wide variety of metal fabrication capabilities and has on occasion worked with manufacturers to prepare and repair their shipped metal parts prior to coating.

This capability saves manufacturers a lot of time and aggravation in the event a product is damaged during shipping to B.L. Downey Company. In the past we have repaired broken metal; added metal; and utilized drilling, grinding, bending, deburring, cutting and other light machining to get customers’ parts quickly ready for coating and shipping.